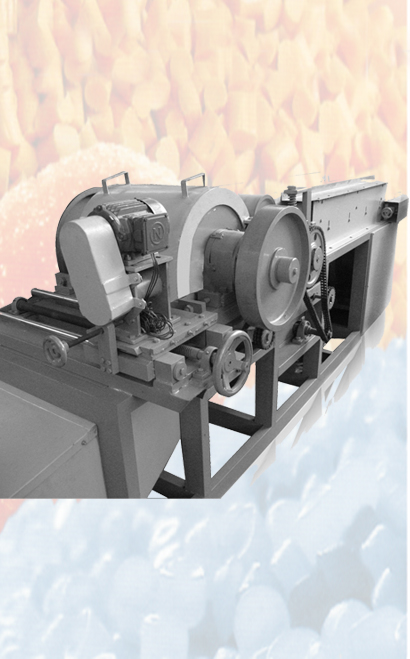

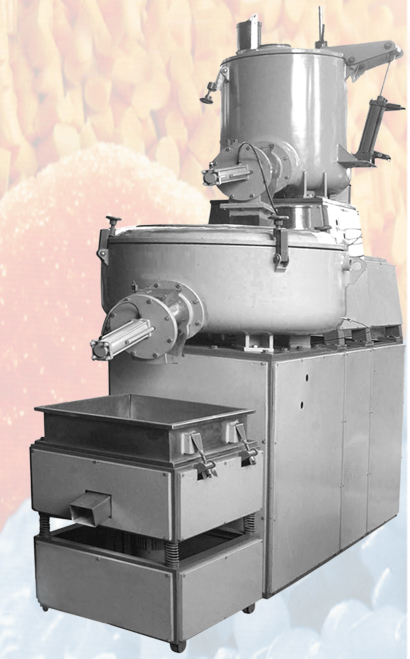

Mixer Cooler Vibrator

WHY WE?

» Efficient production with moisture free Dryblend

» Low compounding cost.

» Compact Space Saving System

» Best quality material of all key components,

» Good Efficiency even with higher calcium loading

» Better Dispersion if the addititive

» Proper design of mixing tools with proper balancing

» Precise peripheral speed of mixing tool.

» With Unquie Design of Bottom & Discharge Valve